Specialty Films

Products

Specialty Films

High‑Performance Specialty Films for Advanced Capacitors

Polypropylene (PP) Film

E-TEK's polypropylene films utilize proprietary PHCM (Polypropylene Heat-sealable Capacitor Material) technology, offering both-side sealable performance through precision heating and extension processes.

Key Features & Certifications

Applications

Hybrid vehicle capacitors (HEV/PHEV)

Electric vehicle components (EV/FCEV)

Film capacitors

Motor applications

Power electronics

Specification

Technical Specification

PP Film (Base Film)

| Property | Specification |

|---|---|

| Available Thickness Range | 2.3μm ~ 2.8μm, 3.0μm, 3.5μm, 4.0μm, 5.0μm, 6.0μm, 7.0μm, 7.5μm, 8.0μm, 9.0μm, 10.0μm, 12.0μm, 15.0μm, 20.0μm, 25.0μm, 30μm ~ 100μm |

| Outer Diameter (OD) | Order made (according to customer requirement) |

| Inner Diameter (ID) | 38mm ±1 or 76mm ±1 |

| Base Material | SYC |

| Features | General PP film for capacitor use |

| Typical Purpose | Capacitor applications |

Heat Sealable PP Film

| Property | Specification |

|---|---|

| Type | Heat sealable capacitor film (PP) |

| Available Thickness | 8μm, 21.5μm, 26.5μm, Other thicknesses: order made |

| Inner Diameter (ID) | 38mm ±1 or 76mm ±1 |

| Base Material | SYC |

| Features | Heat sealable film for capacitor production |

| Typical Purpose | Capacitor applications (heat sealable) |

Polyester (PET) Film

SKC polyester films offer outstanding transparency, tensile strength, and electrical insulation properties. Nontoxic and tasteless with superior dielectric characteristics.

Key Features & Certifications

Applications

Film capacitors

Motor insulation

Electronic component isolation

Power supply applicationsIndustrial electronics

Specification

Technical Specification

PET Film (Base Film)

| Property | Specification |

|---|---|

| Available Thickness Range | 1.4μm, 1.9μm 2.4μm, 2.7μm 3.0μm, 3.3μm, 3.5μm, 3.8μm 4.3μm, 4.6μm, 4.8μm 5.3μm, 5.6μm, 5.8μm 6.8μm, 7.8μm, 8.4μm, 8.5μm 9.8μm 11.3μm, 11.5μm, 11.8μm 12.0μm, 16.0μm 25.0μm, 36.0μm 36.0μm ~ 300μm (extended range) |

| Outer Diameter (OD) | Order made (according to customer requirement) |

| Inner Diameter (ID) | 38mm ±1 or 76mm ±1 |

| Base Material | SKC |

| Features | General purpose PET film for capacitor use |

| Typical Purpose | Capacitor applications |

Heat Sealable PET Film

| Property | Specification |

|---|---|

| Type | Heat sealable PET film for capacitors |

| Available Thickness | 13.5μm Other thicknesses: order made |

| Outer Diameter (OD) | Order made (according to customer requirement) |

| Inner Diameter (ID) | 38mm ±1 or 76mm ±1 |

| Base Material | SKC |

| Features | Heat sealable PET film for capacitor winding and sealing |

| Typical Purpose | Heat sealable capacitor applications |

Metalized Film (PP / PET)

Advanced metalized PP and PET films engineered for demanding capacitor applications. Available in multiple edge patterns and configurations to match your specific manufacturing requirements.

Applications

AC/DC film capacitors

Power electronics

Motor run capacitors

Lighting applications

Power factor correction

Specification

Technical Specification – Metalized Polyester Film (PET)

Thickness (2.4 ~ 16μm)

| Labeling | WMV (μm) | MMV (μm) | Tolerance |

|---|---|---|---|

| 3.5 | 3.5 | 3.7 | ±10% |

| 4.3 | 4.3 | 4.6 | ±10% |

| 4.6 | 4.6 | 4.9 | ±10% |

| 4.8 | 4.8 | 5.1 | ±10% |

| 5.3 | 5.3 | 5.6 | ±10% |

| 5.6 | 5.6 | 5.9 | ±10% |

| 5.8 | 5.8 | 6.1 | ±10% |

| 6.3 | 6.3 | 6.7 | ±10% |

| 6.8 | 6.8 | 7.2 | ±10% |

| 7.8 | 7.8 | 8.2 | ±10% |

| 8.5 | 8.5 | 8.9 | ±10% |

| 9.8 | 9.8 | 10.2 | ±10% |

| 11.5 | 11.5 | 12.0 | ±8% |

| 11.8 | 11.8 | 12.3 | ±8% |

Width / Margin / Diameter

| Width Tolerance | ±10% (기본) |

|---|---|

| Margin Width & Tolerance | below 20mm: ±0.2mm 21 < W < 35mm: ±0.3mm above 35mm: ±0.5mm |

| Outside Diameter | Film width above 10mm: Film width above 15mm: 180 +10 / -20mm |

| Core Inside Diameter | 75mm or 20mm |

Technical Specification – Metallized Polypropylene Film (PP)

Thickness (3.0 ~ 12μm)

| Labeling | MMV Thickness (μm) | Tolerance |

|---|---|---|

| 3.0 | 3.0 | ±10% |

| 4.0 | 4.0 | ±10% |

| 5.0 | 5.0 | ±10% |

| 6.0 | 6.0 | ±10% |

| 7.0 | 7.0 | ±10% |

| 7.5 | 7.5 | ±10% |

| 8.0 | 8.0 | ±10% |

| 9.0 | 9.0 | ±10% |

| 10.0 | 10.0 | ±8% |

| 11.0 | 11.0 | ±8% |

| 12.0 | 12.0 | ±8% |

Width / Margin / Diameter

| Width Tolerance | ±10% |

|---|---|

| Width & Tolerance (mm) | Width below 20mm: ±0.2mm |

| Margin Width & Tolerance | According to MMV design (standard capacitor margin) |

| Outside Diameter | Film width above 10mm: 160mm +10 / -10 |

| Core Inside Diameter | 21mm |

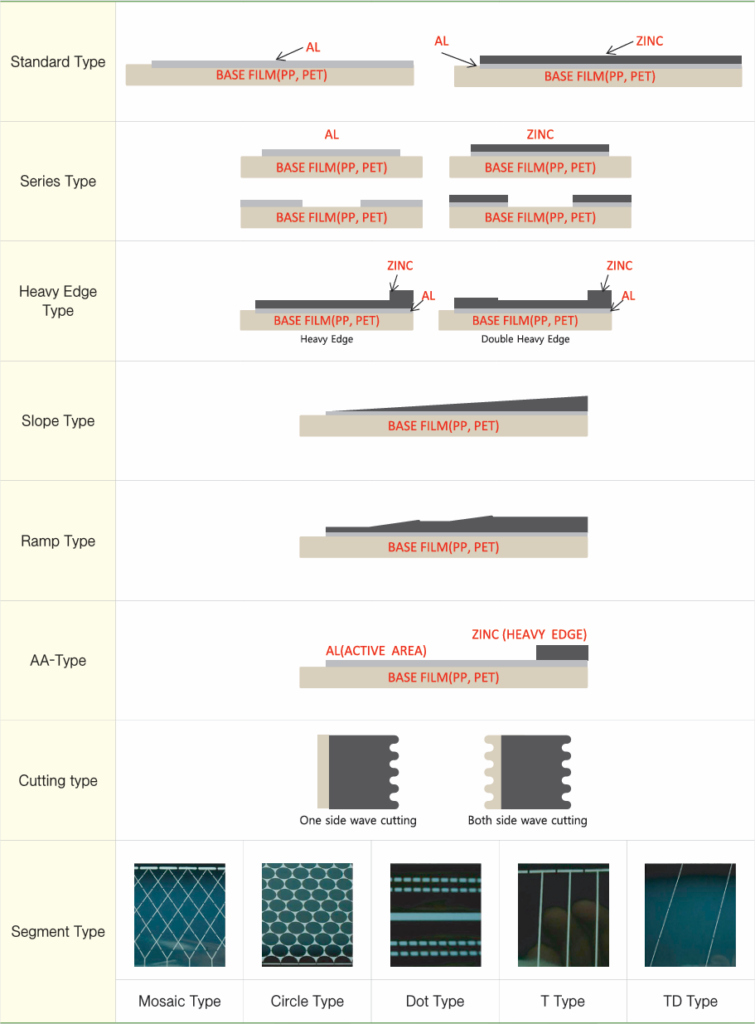

Edge Pattern Options

| Type | Description |

|---|---|

| Standard Type | Single-side metallized base film (PP, PET) with Al or Zn electrode. |

| Series Type | Two metallized sections on one base film for series-connected structures. |

| Heavy Edge Type | Thicker metallized edge area (single or double) for higher current handling. |

| Slope Type | Gradually changing metallized thickness along the film length. |

| Ramp Type | Step‑like change in metallized thickness for controlled current distribution. |

| AA Type | Active Al area with heavy‑edge Zn for improved contact and reliability. |

| Cutting Type | One‑side or both‑side wave cutting on the film edge. |

| Segment Type | Mosaic, circle, dot, T, TD segmented patterns for self‑healing design. |